Quality assurance competence

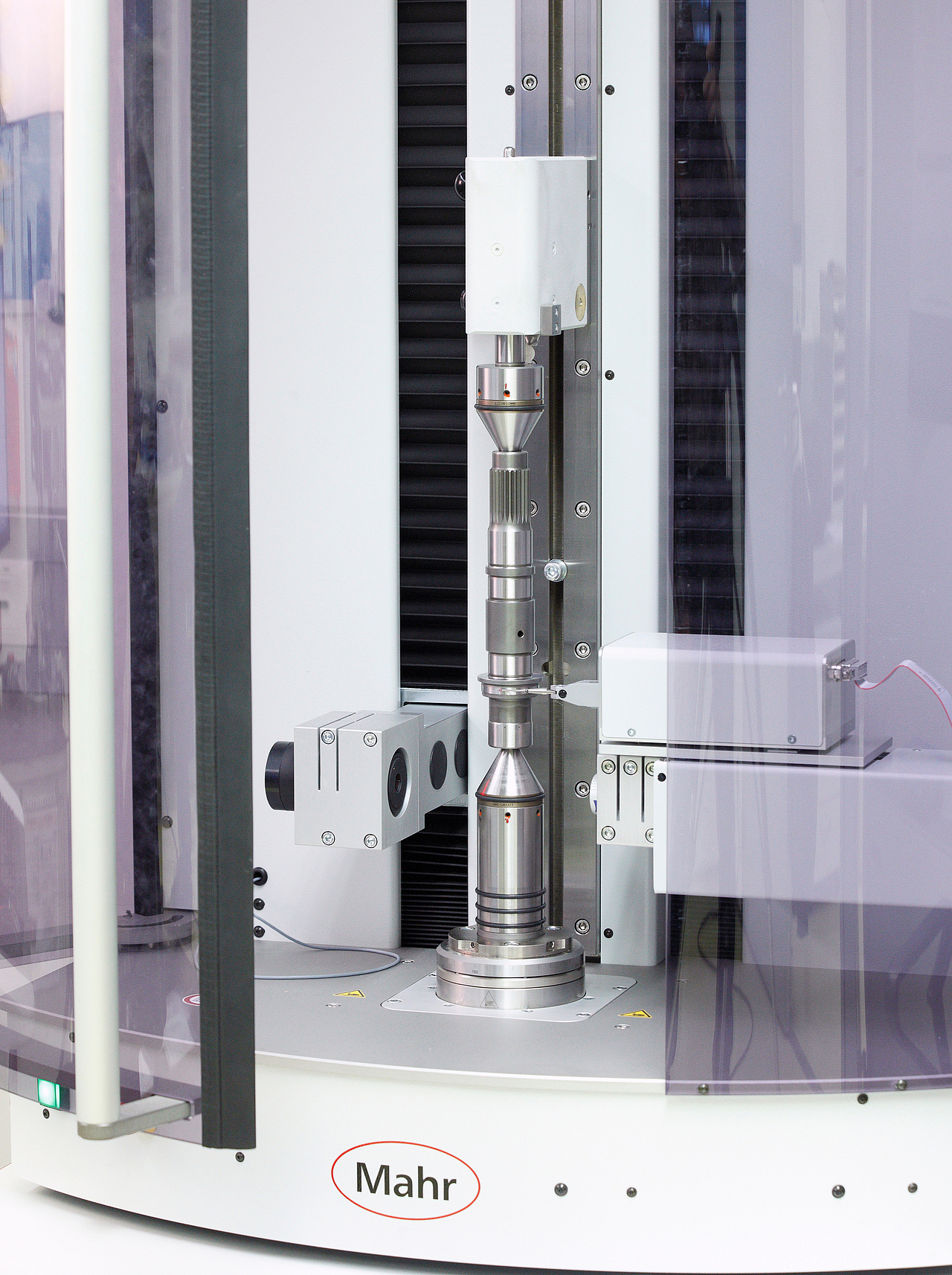

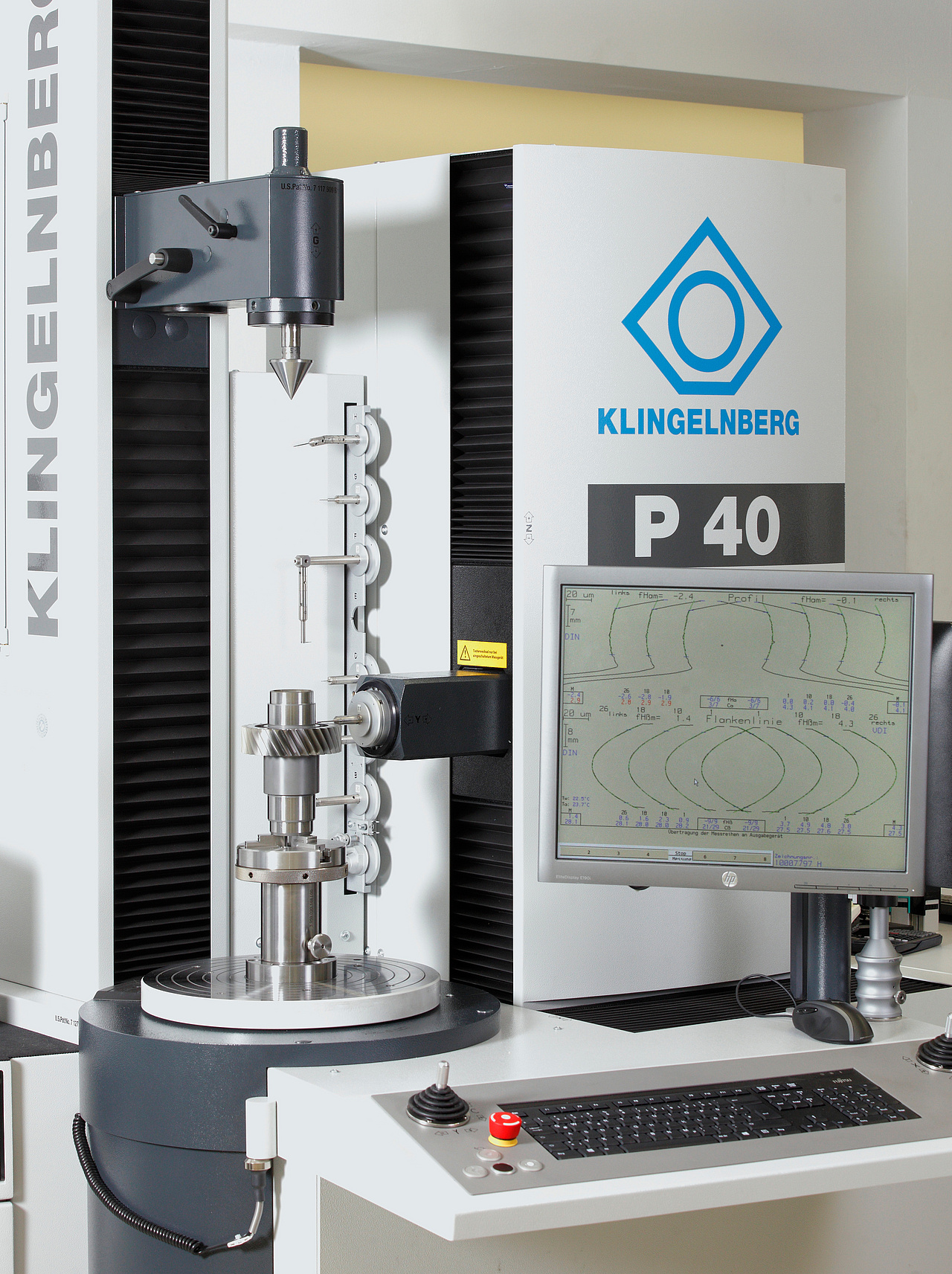

The quality of our products is monitored and tested alongside the manufacture in an air-conditioned and outstandingly equipped measuring room. Modern measuring equipment and the decades of experience and competence of our employees mean that we can always fulfil our customer’s quality requirements.

All our measuring equipment is regularly tested and calibrated by an accredited laboratory.

Measurement technologies:

- Coordinate measurement technology

- Gear tooth measuring technology

- Contour measuring technology

- Surface measuring technology

- Length measuring technology

Management system

Our quality management system is certified to IATF 16949 - the leading standard in the automobile industry. This corresponds to our customers’ strict requirements and our aspiration regarding product quality, productivity, and competitiveness. The satisfaction of our customers and the continuous improvement in our systems and processes are at the focus of our considerations.

The IATF 16949 standard is a global standard for quality management in the automobile industry that applies to manufacturers and suppliers and was published in 2016. The IATF 16949 is based on the ISO 9001 standard, to which Oberaigner has been certified for many years.

An additional concern for Oberaigner is environmental protection. For this reason, we have completed certification to the international standard ISO 14001. Environment management extends over all departments and processes in the company at Oberaigner. The consumption of resources and materials is monitored and permanently optimised, from the products via waste management up to the energy deployed.