Development competence

Oberaigner Powertrain is a system supplier (Tier 1 Supplier) for drive technology for small to medium-sized annual production rates. As a specialist in this field, Oberaigner is able to offer complete new developments of system modules and units, and to implement derivative developments and special solutions quickly, efficiently and at the highest level.

Oberaigner is available the competent partner in development and production of product variants and vehicle equipment items which are uneconomical for the vehicle manufacturers (OEM) to produce on account of the small quantities involved. Oberaigner has decades of experience and know-how in the special field of retro-integration of all-wheel drive systems in light commercial vehicles (LCV). The exploitation of synergies with existing OEM products plays a significant role in this regard.

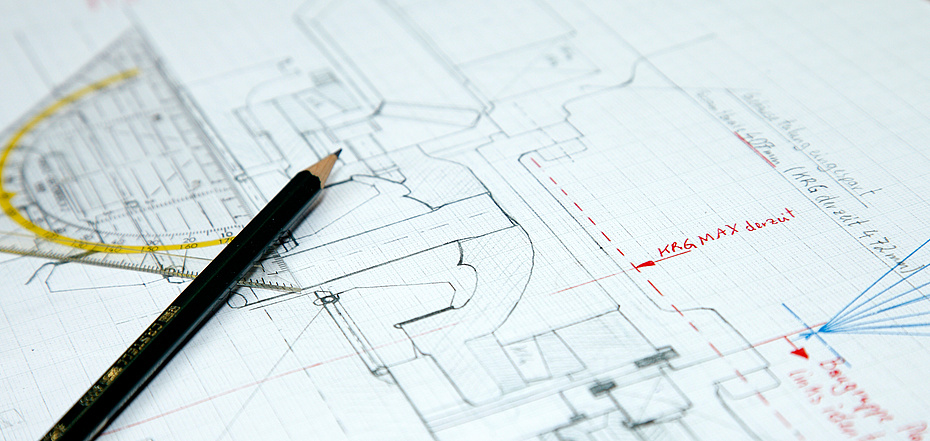

The responsibility for the system covers the mechanical, mechatronic, and electrical/electronic sub-systems. The framework of processing of overall projects illustrates the following intermediate steps:

- Feasibility study

- Project planning

- Detailed development

- Detailed optimisation

- Process development

- Prototype production

- Testing

- Series start-up

- Series mentoring

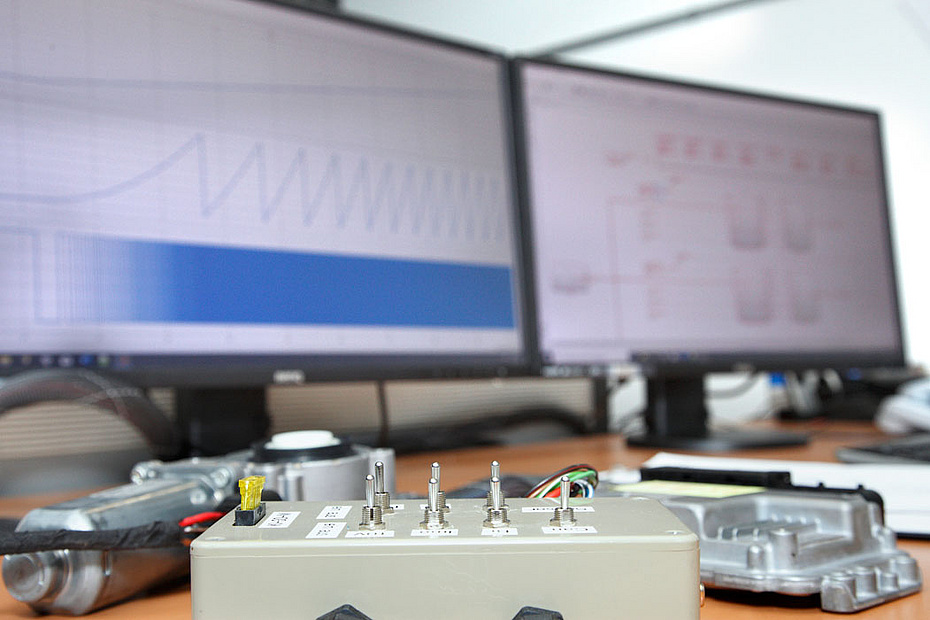

We generate model-based approaches for function development based on a fundamental mechatronic consideration of the entire system. The feasibility verification (Proof of Concept) for these approaches is generated within the company using fast model construction (Rapid Prototyping).

The mechanical elements of the drive components are manufactured and installed in-house. Oberaigner’s core competence is the production-oriented development of system-relevant drive components.

Development takes place as in-house or order development - depending on the objective.

Oberaigner positions itself caught between small volumes and high automotive standards. The topics of vehicle integration and NVH behaviour and the effectiveness of the drive systems play a special role in this regard. The electrical and electronic components (E/E components) are implemented with renowned suppliers from the vehicle manufacture sector. As a result of this partnership collaboration with these renowned suppliers, Oberaigner is also able to illustrate overall systems as the responsible entity for those items extending beyond the core competencies of Oberaigner.

Challenging project framework conditions are part of our daily routine. This also includes critical technical requirements, such as restricted installation space and the implementation and incorporation of derivative developments in existing large series environments.

Oberaigner aspires to offer these solutions in a product and process quality that corresponds to the standard requirements of the OEMs, matched to, and optimised for, the special framework conditions of small series runs and special solutions.