Brief introduction

Oberaigner Powertrain GmbH was opened for business in February 2002 in Nebelberg in Austria, right next to the German border.

This step was necessary because the old company headquarters in Rohrbach was not designed to accommodate the growth in the company. This included a legal separation of the business sectors All-Wheel drive Technology and Mercedes-Benz authorised workshop, which continues to be successful in this location.

The works in Nebelberg covers an area of more than 6,500 m² of manufacturing and assembly shops, with an incorporated warehouse and administration building. Test drives on the premises are possible on our extensive works property.

Product quality and company success are emphasised once again by the following figures:

- Export quota of more than 90%

- Deployment of our products all over the world under all climatic conditions

- Long-term partnership with renowned automobile manufacturers, such as

MAN, Mercedes-Benz, Renault, Nissan, Volkswagen

Products and services

Alongside series production and installation of transfer cases and front axle final drives, the Nebelberg facility is characterised particularly by high competence levels in the fields of development, testing and prototype construction.

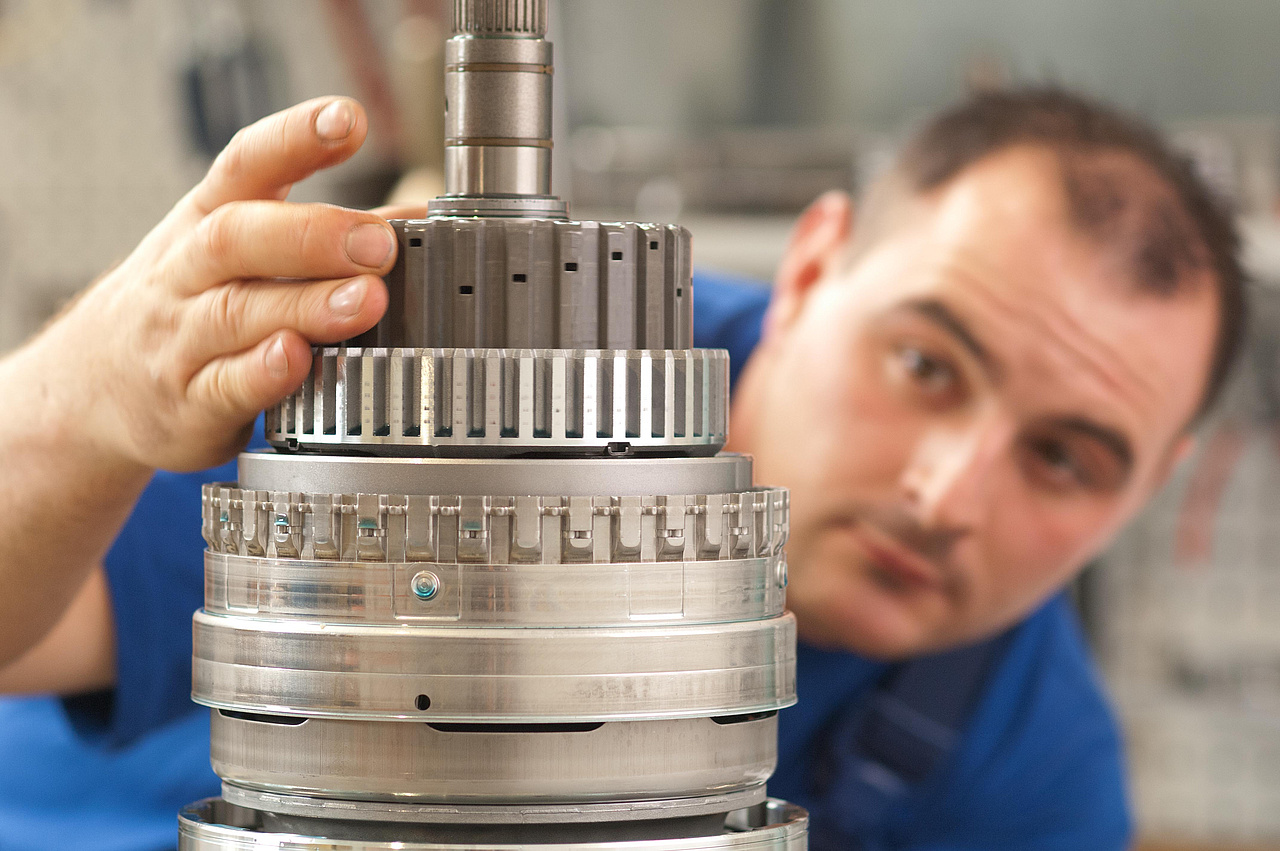

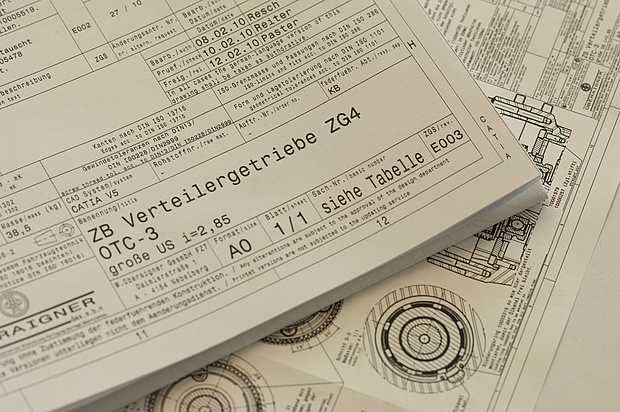

All machining steps in the manufacture of transmission gearboxes, such as turning, milling, grinding, honing, deburring and gear-cutting, are carried out in-house at Oberaigner. Computer-supported and computer-monitored assembly ensures that the in-house-developed gearboxes meet the highest quality standards and are incorporated in large series runs by renowned automobile manufacturers.

We look forward to being able to submit a non-binding and free-of-charge tender to you. Please get in touch.

Performance portfolio

DMG NLX2500Y-/ 700

Okuma MacTurn 350-W

WFL Milturn M30-G-/ 1000

Bridgeport Conquest V1000

Okuma MA-50HA

Okuma MA-500HA

Okuma MA-500H II

Kellenberger UR 225-/ 1000

Kellenberger Varia

Reishauer RZ400

Gleason Pfauter GP300 ES

Gleason Pfauter P300

Gleason Pfauter PSA300

Fässler HMX-400

TFG – RGC 350

Fastems High-Rack

Frai (industrial robot)

MAGtech (industrial robot)

- Turning

- Milling

- Grinding

- Gear-cutting

- Gear tooth flank grinding

- Gear honing

Development at a high level

No compromising in quality and performance

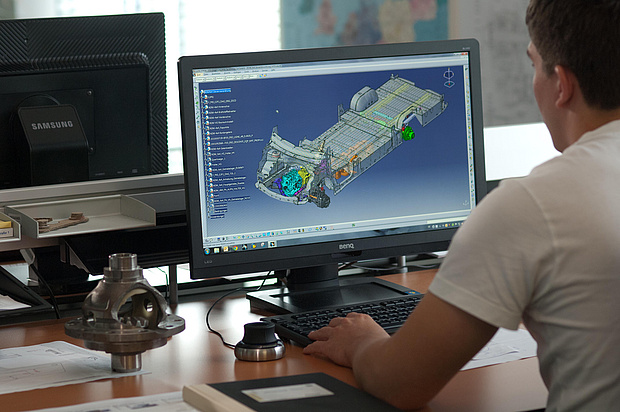

From gearboxes, axles, vehicle components, and systems, via assembly kits to complete vehicles in the field of the smallest and small series runs, Oberaigner can rely on decades of experience and competence.

Our competences are particularly in the entire vehicle drive train, including axles and axle suspension, in particular in the field of all-wheel drive technology and in special gears for special applications.

Oberaigner is a long-standing system supplier to the automobile industry, and is certified to IATF 16949. We are able to ensure services both for our in-house development and for our customers by continuous development of our management and QA systems by the use of the latest equipment and methods.

The components, assemblies, systems and vehicles developed at Oberaigner are subject to comprehensive tests and investigations in accordance with the current standards in the automobile industry, or in accordance with the stipulations of our customers. With regard to the performing of various different investigations, and the evaluation of results, we work very closely both with purchasers and with competent service providers, partners and scientific installations, so that we can offer our customers the best and safest product.

Purchasing

Partnership is the key to success

Competitive products and maximum customer benefit are the prime considerations for the Oberaigner Group - both in collaboration with international customers and with worldwide suppliers.

Oberaigner has the following supplier requirements:

- Standard parts

- Forged parts

- Cast parts

- Bar material

- Vehicle components

- Jobbing manufacture (hardening, grinding, gear-cutting, coatings, turning, milling)

Based on the growth in business, purchasing requirements will continue to increase in coming years.

The requirements for collaboration are challenging - but, in return, Oberaigner offers good growth perspectives for their suppliers, together with long-term, trusting and partnership-centred business relationships.

Our purchasing conditions and guidelines for suppliers have exclusive validity. These can be seen in the download area.